Select the open top type when moving the device in and out by auto loader, and the clamshell type when inserting and removing it by hand.

Burn-in sockets for CPU / GPU

Supported Packages

-

Burn-in Sockets

Reliability Assessment /

For Mass Production -

Test Sockets

Property Assessment /

For Mass Production

Burn-in (BI) sockets for CPU / GPU with a large PKG are likely expensive due to a large number of pins, so the key point is how to design and manufacture a socket that meets the specifications of the device while keeping costs down. Enplas Semiconductor Peripherals, the owner of this IC Socket Solutions.com, offers low-priced general-purpose frames whose size are optimum according to the PKG O.D., from a small socket for mobile devices to a large socket for servers. In addition, the parts related to PKG balls and pads, and the parts related to thermal control can be optimized according to the requirement. Furthermore, by tooling up for not only the plastic parts of the frame but also the contact pins, the socket that uses thousands of pins for medium~large devices are composed of significantly low-cost parts.

Key points for selecting a BI sockets for CPU / GPU Points

For BI sockets for CPU / GPU, it is necessary to select the optimum specifications depending on the usage, environment, and the function of device. Here are important points in determining the specifications of BI sockets for CPU / GPU

Point#1

Select the method of setting the device from either open top or clamshell

Point#2

Select a product with temperature control function or anti-static measures depending on the test environment

When conducting a high temperature test, select a socket with a heater / sensor for temperature control. It is also possible to use ESD-compatible materials when antistatic is required.

Point#3

Take further heat dissipation measures, if the PKG output is high and there is concern about heat generation.

If the PKG output is high and it generates heat, it is necessary to optimize the structure and shape by using a heat sink / heat pipe or heat spreader for liquid-cooled ovens in order to improve heat dissipation efficiency.

Point#4

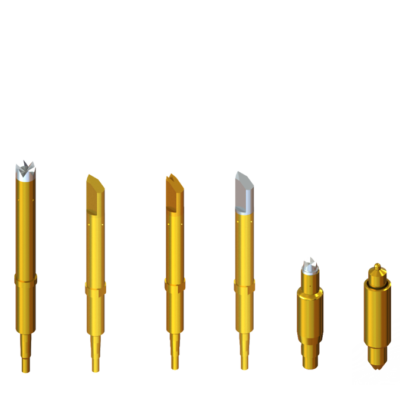

Select the most suitable contact pin according to the required electrical characteristics

If low inductance is required, select a capsule contact pin that supports high frequencies, and if the current value is large, select a probe pin.

Common problems of Burn-in sockets for CPU / GPU Issues

Since BI sockets for CPU / GPU need to keep stable performance even in harsh environments, it is necessary to incorporate measures to avoid troubles in advance by utilizing simulation technology. Here are common problems and solutions when using sockets for BI sockets for CPU / GPU

Issue #1

Since the PKG has a large O.D. and requires a large number of pins, it will inevitably be expensive.

BI sockets for CPU / GPU, especially a large CPU PKG for servers and a high-end large GPU PKG, will likely be expensive because they are larger than the general-purpose PKGs, so will need fully-machined frames. Also, the number of pins will be very large, so the total cost will increase.

Solutions

With general-purpose frames using molded components and stamped contact pins, we offer inexpensive IC socket for whatever PKG O.D.

Issue #2

Only a small number of sockets are needed when a similar PKG is developed.

IC sockets for CPU / GPU with large O.D. and many pins tend to be expensive compared to sockets for other devices. Therefore, if sockets for a similar package is needed, such as when producing multiple projects at the same time, the cost will increase.

Solutions

Reduced socket unit price with inexpensive molded general-purpose frames

Issue #3

Requirement for socket that fits a specific BI oven

Since the size restrictions such as the height of the socket differ depending on each BI oven, the socket for CPG / GPU needs to accommodate these differences flexibly.

Solutions

Enplas can propose appropriate sockets compatible with various BI ovens sold in the market, such as a low profile socket.

Burn-in sockets for CPU / GPU

Supported Packages

Our socket solution for burn-in CPU / GPU Solutions

IC Socket Solution.com provides IC socket solutions that apply abundant achievements and simulation technology to all the problems that occur when burn-in testing CPU / GPU.

-

Spring Probe Pin

Enplas's own design will provide internal short circuit of probe pin with low resistance value (Ave 50m ohm or under)

Enplas provides suitable socket design proposal to meet required specification -

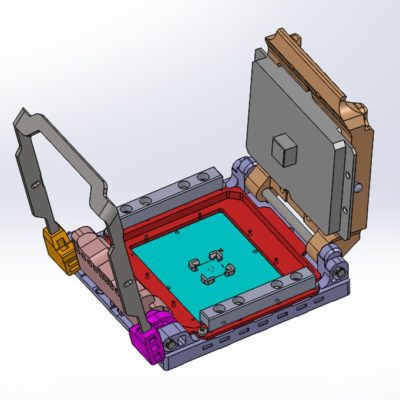

Custom socket for high power liquid cooling system

Not only BGA, and LGA, but also various type of package including QFN can be designed by using a socket that is suitable for the thermal head size

-

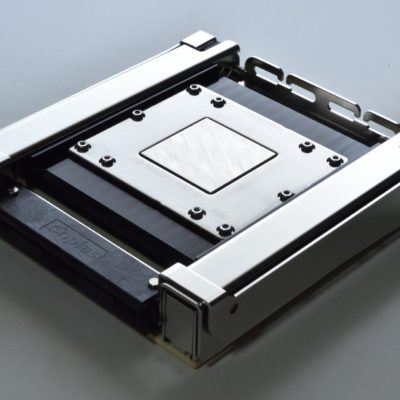

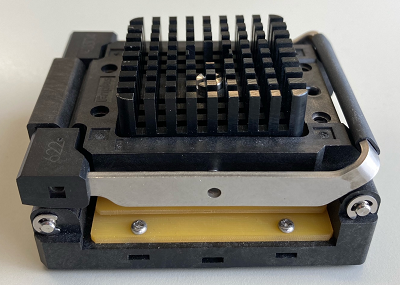

LCF series (general-purpose molded frame)

Low price and quick delivery for various devices up to 100mmx100mm

Replacible on site by surface mounting method -

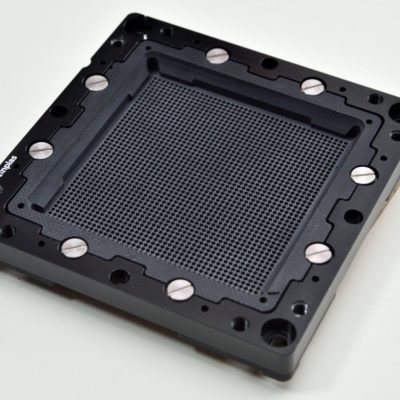

Improved cover handling socket for large devices

Enable to operate with stable pressing force for high pin count solutions.

-

Height adjustable socket

By just switching a lever, the height of Heat sink pressing surface is adjusted to enable one IC socket to test PKGs of different thickness.

-

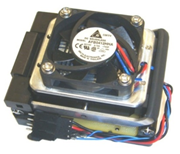

Socket with heat sink

Heat Sink will reduce the increase of device temperature by contacting device surface with this parts and radiating the device heat into the air.

-

Burn-in socket with heat pipe

High heat dissipation performance due to the heat circulation structure of the heat pipe improves the accuracy of individual temperature adjustment tests for high heat generation PKG.

-

Individual Temparature Control System

Heater and temperature sensors can be attached to control the temperature of the device for each socket.

Achieves more accurate temperature control in comparison with general burn-in equipment (temperature setting ± 3 ° C) -

High pin count BGA socket (VC contact)

Stamped contact pin and molded frame realize significant cost reduction for large PKG

Replacible on site by surface mounting method -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc. -

AM contact series

Low price and quick delivery for various devices by using machined Contact unit

Replacible on site by surface mounting method

Please feel free to contact us with

your questions regarding burn-in sockets.

Contact Us

- Is it possible to manufacture a socket with more than 10,000 pins?

- I am considering an electrical inspection methods for LGA ceramic packaging (20 to 50 mm) with several thousand pins. Do you have a suitable socket for this device?

- Is it possible to support high pins counts of BGA socket?

- How do you prevent the BGA heating with the socket ?

- Can the BGA socket support ultra-fine pitch?

- What kind of analysis can you provide ?

- Is there export to overseas and get local support?

- What should I do if there is a problem?

- What is the guaranteed cycle?

- What temperature can it be used in?

- I would like to consider a burn-in socket, but what information do you need?

- How long does it take to deliver?

For Test sockets for CPU / GPU, it is important to select and adopt the most suitable contact pins according to the electrical characteristics of the device. The pin tip which contacts PKG ball or pad can be optimized by customizing the shape reflecting requirements. Furthermore, IC Socket Solution.com introduece various solution from small sockets with fine pitch for mobile application to large sockets with large pitch for server application.

In addition, by tooling up for contact pins, the total cost of the pin can be significantly reduced even in the case of sockets that use thousands of pins for medium to large devices.

Key points for selecting Test sockets for CPU / GPU Points

For Test sockets for CPU / GPU, it is necessary to select the optimum specifications depending on the usage, environment, and the function of device. Here are important points in determining the specifications of Test sockets for CPU / GPU.

Point#1

Select the socket mechanism according to the test environment and purpose

When using in mass production test, select the type without pressing mechanism. If manual evaluation is also cunducted, select double latch type or clamshell type.

Point#2

Select the most suitable contact pin according to the required electrical characteristics

If high frequency characteristics are required, select a pin that can minimize insertion loss and return loss, such as Capsule contact socket or Coaxial contact pin.

Point#3

Select the material of the contact pin tip according to the required durability

In order to improve durability or to prevent Sn from adhering to the contact pin, there are options for the contact pin tip, carbon coating, palladium alloy or SK material. These lead to improved life and contact stability

Point#4

Select the housing material depending on what matters

Consider whether to adopt a cost-effective material or a material that maximizes the performance of the pin.

Common problems of Test sockets for CPU / GPU Issues

Since Test sockets for CPU / GPU need to keep stable performance even in harsh environments, it is necessary to incorporate measures to avoid troubles in advance by utilizing simulation technology. Here are common problems and solutions when using sockets for Test sockets for CPU / GPU

Issue #1

Since the PKG has a large O.D. and requires a large number of pins, it will inevitably be expensive.

Test sockets for CPU / GPU, especially a large CPU PKG for servers and a high-end large GPU PKG, will likely be expensive because they are larger than the general-purpose PKGs, so will need fully-machined frames. Also, the number of pins will be very large, so the total cost will increase.

Solutions

With stamping technology to manufacture contact pins, any PKG outline can be handled with low cost

Issue #2

Only a small number of sockets are needed when a similar PKGs are developed.

IC sockets for CPU / GPU with large O.D. and many pins tend to be expensive compared to sockets for other devices. Therefore, if sockets for each similar package are needed, such as when producing multiple projects at the same time, the cost will increase.

Solutions

Reduced socket unit price with inexpensive molded general-purpose frames

Issue #3

Requirement for High frequency band

Test sockets for CPU / GPU are required to support high speed signal measurement in Final Test, it is necessary to select a high performance contact pin according to the required electrical characteristics.

Solutions

Use the optimum combination according to the required electrical characteristics and minimize the cost!

Use Capsule contact pin, which has short total length!

Use Coaxial contact pins, which is impedance-matched!

Burn-in sockets for CPU / GPU

Supported Packages

Our socket solution for Test CPU / GPU Solutions

IC Socket Solution.com provides IC socket solution that applies abundant achievements and simulation technology to all the problems that occur when final testing CPU / GPU.

-

Spring Probe Pin

Enplas's own design will provide internal short circuit of probe pin with low resistance value (Ave 50m ohm or under)

Enplas provides suitable socket design proposal to meet required specification -

Test socket with heat pipe

The high heat dissipation capacity enabled by the heat pipe's thermal circulation structure allows for the measurement of devices with high-heat-emitting packages.

-

Conductivity Carbon Coating

Achieved a significant longer life of contacts by preventing solder migration

Achieved high durability with high slidablity and hardness -

Capsule contact

The short-length probe pin structure (total length 1.5 mm) realizes good high-frequency characteristics.

Ideal for high-speed transmission and low-voltage products -

Coaxial Contact Pin

Coaxial structure is the most suitable solution for high frequency characteristics requirement.

Minimizes crosstalk performance with shielded metal housing. -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc.

Please feel free to contact us with

your questions regarding test sockets.

Contact Us

- Is it possible to manufacture a socket with more than 10,000 pins?

- Are there sockets for writing program data?

- I am considering an electrical inspection methods for LGA ceramic packaging (20 to 50 mm) with several thousand pins. Do you have a suitable socket for this device?

- Is it possible to support high pins counts of BGA socket?

- Is it possible to support high frequencies in the BGA test socket?

- Can the BGA socket support ultra-fine pitch?

- What kind of analysis can you provide ?

- Is there export to overseas and get local support?

- What should I do if there is a problem?

- What is the guaranteed cycle?

- What temperature can it be used in?

- I would like to consider Enplas’s test socket. What kind of information I need to provide ?

- How long does it take to deliver?