Solutions

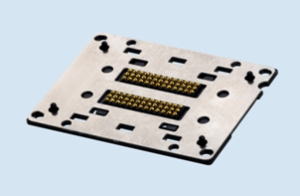

Low Contact Force Pin

- High pin count socket can be used for existing equipment

- Yield improvement in test of sensor device

Recent device development trend is larger device size with higher pin count to meet electric equipments’ multi-functionalized. With keeping current ATE’s push force and use of high pin count socket, we developed low contact force pin with our own tip shape and probe pin internal structure.

With lower contact force pin, we can prevent the warpage of device center such as image sensor, which device center can not be pushed.

Using low force contact pin, we can provide cost effective solution because the user does not have to invest new equipment and reduce the time loss and yield loss due to device warpage

Examples of IC Socket Solutions Solution Examples

- All Solutions

- Choose by application

- Choose by device

- Choose by PKG

- Choose by issue

Examples of CPU/GPU Solutions

-

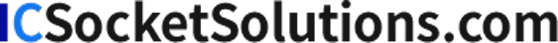

Spring Probe Pin

Enplas's own design will provide internal short circuit of probe pin with low resistance value (Ave 50m ohm or under)

Enplas provides suitable socket design proposal to meet required specification -

Curling Contact Series

Cost saving solution with the same performance as probe pin

Long stroke pin which works for device warpage in accordance with recent large size device -

Low Contact Force Pin

High pin count socket can be used for existing equipment

Yield improvement in test of sensor device -

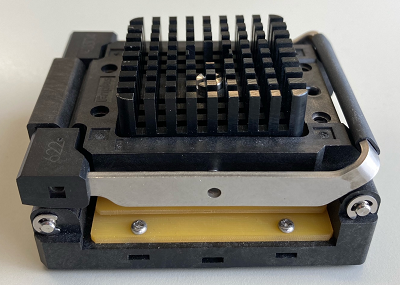

Custom socket for high power liquid cooling system

Not only BGA, and LGA, but also various type of package including QFN can be designed by using a socket that is suitable for the thermal head size

-

LCF series (general-purpose molded frame)

Low price and quick delivery for various devices up to 100mmx100mm

Replacible on site by surface mounting method -

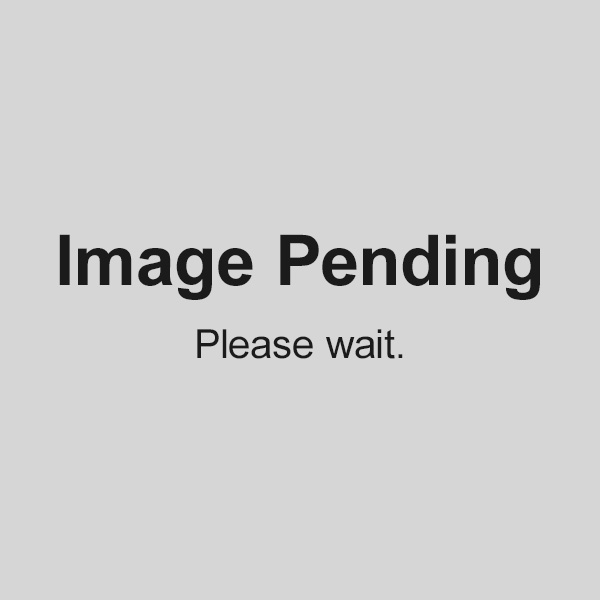

Improved cover handling socket for large devices

Enable to operate with stable pressing force for high pin count solutions.

-

Height adjustable socket

By just switching a lever, the height of Heat sink pressing surface is adjusted to enable one IC socket to test PKGs of different thickness.

-

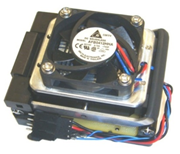

Socket with heat sink

Heat Sink will reduce the increase of device temperature by contacting device surface with this parts and radiating the device heat into the air.

-

Burn-in socket with heat pipe

High heat dissipation performance due to the heat circulation structure of the heat pipe improves the accuracy of individual temperature adjustment tests for high heat generation PKG.

-

Test socket with heat pipe

The high heat dissipation capacity enabled by the heat pipe's thermal circulation structure allows for the measurement of devices with high-heat-emitting packages.

-

Individual Temparature Control System

Heater and temperature sensors can be attached to control the temperature of the device for each socket.

Achieves more accurate temperature control in comparison with general burn-in equipment (temperature setting ± 3 ° C) -

Conductivity Carbon Coating

Achieved a significant longer life of contacts by preventing solder migration

Achieved high durability with high slidablity and hardness -

High pin count BGA socket (VC contact)

Stamped contact pin and molded frame realize significant cost reduction for large PKG

Replacible on site by surface mounting method -

Capsule contact

The short-length probe pin structure (total length 1.5 mm) realizes good high-frequency characteristics.

Ideal for high-speed transmission and low-voltage products -

Coaxial Contact Pin

Coaxial structure is the most suitable solution for high frequency characteristics requirement.

Minimizes crosstalk performance with shielded metal housing. -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc. -

AM contact series

Low price and quick delivery for various devices by using machined Contact unit

Replacible on site by surface mounting method