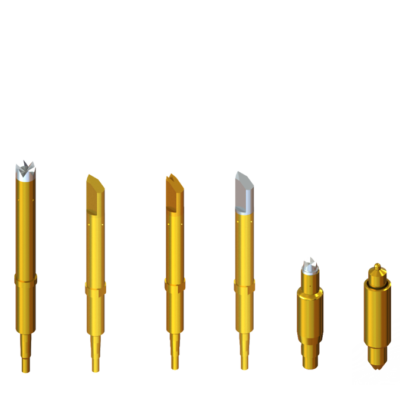

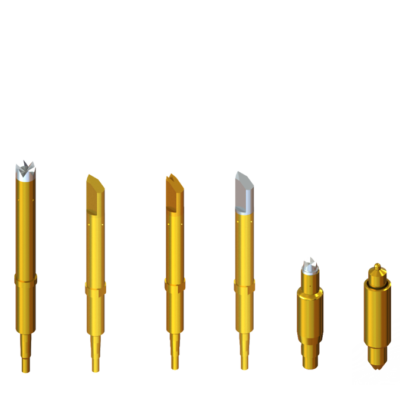

The package for AP will be fine pitch, so, we choose the contact pin for fine pitch (0.4mm, 0.35mm, 0.3mm).

Socket for Application Processor

Supported Packages

-

Burn-in Sockets

Reliability Assessment /

For Mass Production -

Test Sockets

Property Assessment /

For Mass Production

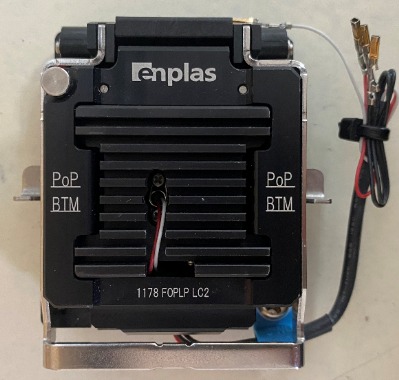

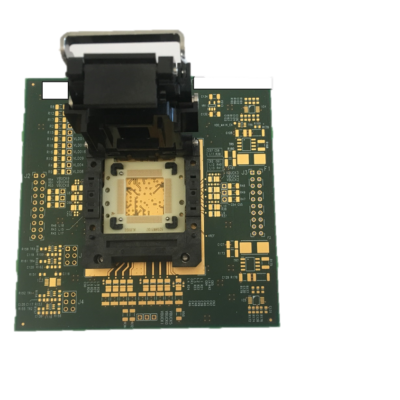

Application processor is considered as the brain of the smart phone, so, the device has smaller pitch and higher pin count to meet the requirement of high performance/high speed. Consequently, the socket also needs to support smaller pitch and higher pin count. Enplas provides such socket as fine-pitch socket, high pin count socket, or special type of socket for PoP package.

Burn-in socket for application processor is used under high temperature environment with the package. Therefore, the socket with heater and sensor will be used in order to control pakage temperture under various temperature environment.

Fine pitch/high pin count device for application processor generates a lot of head due to high wattage, so, socket needs to have heat readiation perforamnce. Using thermal simulation, we design heatsink or heat pipe, and propose customized socket to the customer.

Key points for selecting a BI Socket for Application Processor Points

For BI sockets for Application Processor, it is necessary to select the optimum specifications depending on the usage, environment, and the function of device. Here are important points in determining the specifications of BI sockets for CPU / GPU

Point#1

Choose contact pin for fine pitch which is the characteristic of the socket

Point#2

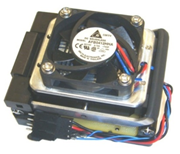

Choose temperature control function option or electrostatic countermeasure component option

The socket with heater/sensor which is for temperature control in high temperature test will be used. Also, we can choose ESD compliant component for antistatic requirement.

Point#3

Additional heat radiation measure option for further heat generation due to high power device

In case of high heat generation package with high wattage, customized heat sink shape/ heat pipe or heat spreader for liquid thermal control system will be used in addition to thermal control function.

Point#4

Choose suitable contact pin based on required electric characteristic

High frequency compliant cupsel contact pin for low inductance or probe pin for high current will be selected

Common problems of Burn-in sockets for Application Processor Issues

Since BI sockets for Application Processor need to keep stable performance even in harsh environments, it is necessary to incorporate measures to avoid troubles in advance by utilizing simulation technology. Here are common problems and solutions when using sockets for BI sockets for Application Processor

Issue #1

Device high heat due to fine pitch

Application processor trend is fine pitch and high pin count for high speed and high functionality among increasing number of smartphone components. Therefore, the fine pitch device is easy to creat the heat and has the possilibty of thermal runaway during burn in test.

Solutions

Select customized design of heat sink based on thermal simulation result

Issue #2

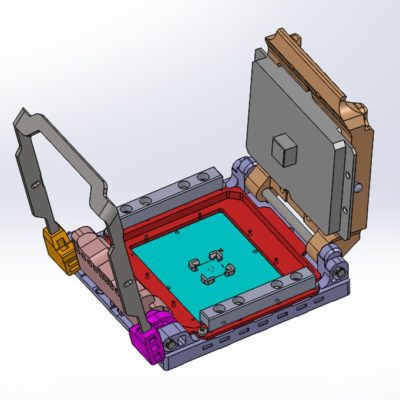

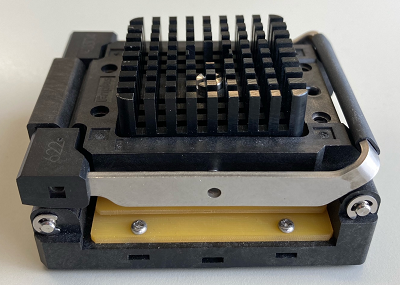

Different thickness device test in 1 socket

For PoP package, we have the test case of one side test other than the test with upper and lower side package. For such test, usually 1 socket works for 1 type of thickness, so, if thickness is different, the customer needs to obtain multiple socket corresponednce to the thickness type.

Solutions

Height adjustmnet socket will work for different thickness device.

Efficiency of test will be up.

Issue #3

Socket cost incresed due to fine pitch or higher pin count

The cost of burn in socket for application processor becomes higher due to fine pitch and higher pin count. In addition, conventional burn in socket requires initial cost, so, new idea for cost reduction is reuiqred

Solutions

Cost reduction proposal with AM contact series socket

Socket for Application Processor

Supported Packages

Our socket solution for AP burn-in process Solutions

IC Socket Solutions.com offers IC socket solutions that apply a wealth of experience and simulation technology to all the challenges that arise when burn-in testing for AP

-

Spring Probe Pin

Enplas's own design will provide internal short circuit of probe pin with low resistance value (Ave 50m ohm or under)

Enplas provides suitable socket design proposal to meet required specification -

Custom socket for high power liquid cooling system

Not only BGA, and LGA, but also various type of package including QFN can be designed by using a socket that is suitable for the thermal head size

-

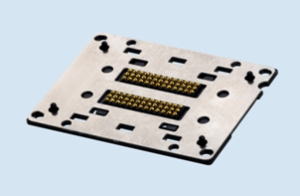

LCF series (general-purpose molded frame)

Low price and quick delivery for various devices up to 100mmx100mm

Replacible on site by surface mounting method -

Carrier Socekt

Easy package handling with carrier PCB

Multi-height pusher for different thickness devices -

Improved cover handling socket for large devices

Enable to operate with stable pressing force for high pin count solutions.

-

Height adjustable socket

By just switching a lever, the height of Heat sink pressing surface is adjusted to enable one IC socket to test PKGs of different thickness.

-

Socket with heat sink

Heat Sink will reduce the increase of device temperature by contacting device surface with this parts and radiating the device heat into the air.

-

Individual Temparature Control System

Heater and temperature sensors can be attached to control the temperature of the device for each socket.

Achieves more accurate temperature control in comparison with general burn-in equipment (temperature setting ± 3 ° C) -

High pin count BGA socket (VC contact)

Stamped contact pin and molded frame realize significant cost reduction for large PKG

Replacible on site by surface mounting method -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc. -

AM contact series

Low price and quick delivery for various devices by using machined Contact unit

Replacible on site by surface mounting method

Please feel free to contact us with

your questions regarding burn-in sockets.

Contact Us

- Is it possible to manufacture a socket with more than 10,000 pins?

- Is it possible to support high pins counts of BGA socket?

- How do you prevent the BGA heating with the socket ?

- Can the BGA socket support ultra-fine pitch?

- What kind of analysis can you provide ?

- Is there export to overseas and get local support?

- What should I do if there is a problem?

- What is the guaranteed cycle?

- What temperature can it be used in?

- I would like to consider a burn-in socket, but what information do you need?

- How long does it take to deliver?

Application processor is considered as the brain of the smart phone, so, the device has smaller pitch and higher pin count to meet the requirement of high performance/high speed. Consequently, the socket also needs to support smaller pitch and higher pin count. Enplas provides such socket as fine-pitch socket, high pin count socket, or special type of socket for PoP package.

The number of use time for test socket is higher than that for burn-in socket because final test is short test time. So, long life time measuer of the socket is required and we are expected to include such feature in the spec of test socket.

Key points for selecting Test sockets for Application Processor Points

For Test sockets for Application Processor, it is necessary to select the optimum specifications depending on the usage, environment, and the function of device. Here are important points in determining the specifications of Test sockets for Application Processor.

Point#1

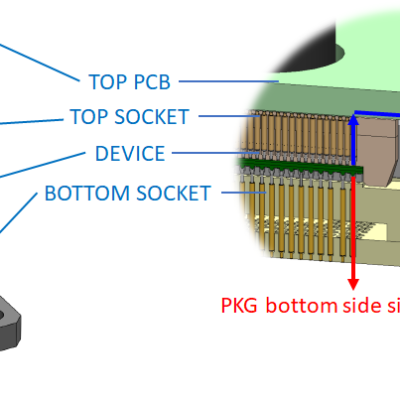

PoP compatible socket will be selected for Pop PKG test

When AP is PoP PKG case, PoP compatible socket will be selected for both contact of pad on PKG and ball on lower side.

Point#2

Suitable contact pin or probe pin will be selected for fine pitch requirement

Suitable cupsle contact pin or probe pin will be selected for fine pitch requirement, such as 4mm or smaller pitch of pkg ball.

Point#3

Choose the material of contact pin tip based on required life time

In order to increase the abrasion resistance, we have several solution. Carbon coating on pin tip or change of the material on pin tip into Pd alloy or carbon tool steel material (SK material) will bring better abrasion resistance or stabe contact performance with avoiding Sn waste on pin tip.

Point#4

The most suitable pin will be selected for electric characteristics.

Cupsle contact or coaxial contact will be selected for high required spec (for example high frequency requirement)

Common problems of Test sockets for Application Processor Issues

Test socket for AP application requires the stable performance under severe condition, so, we need to prepare the measure to avoid the trouble which will be anticipated in advance. We offer the solution for the problems which are frequently asked.

Issue #1

High frequency requirement for the socket

Test socket for AP purpose require the capability of the measurement for high speed signal. Usual contact pin does not meet such requirement, so, we need to select the suitable contact pin for it

Solutions

Short length capsule contact pin will be the choice.

Also, Coaxial contact pin with impedance matching will be the solution.

Issue #2

The socket compatible with PoP type device is required

PoP type package requires the socket with high accuracy on the test due to the contact on upper/bottom array in the same time. Usual test socket can contact only single side.

Solutions

PoP compatilbe socket will be the choice

Socket for Application Processor

Supported Packages

Our socket solution for AP Test purpose Solutions

IC Socket Solution.com provides IC socket solution that applies abundant achievements and simulation technology to all the problems that occur when conducting the final test of AP.

-

Spring Probe Pin

Enplas's own design will provide internal short circuit of probe pin with low resistance value (Ave 50m ohm or under)

Enplas provides suitable socket design proposal to meet required specification -

Conductivity Carbon Coating

Achieved a significant longer life of contacts by preventing solder migration

Achieved high durability with high slidablity and hardness -

Capsule contact

The short-length probe pin structure (total length 1.5 mm) realizes good high-frequency characteristics.

Ideal for high-speed transmission and low-voltage products -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc.

Please feel free to contact us with

your questions regarding test sockets.

Contact Us

- Is it possible to manufacture a socket with more than 10,000 pins?

- Are there sockets for writing program data?

- Is it possible to support high pins counts of BGA socket?

- Is it possible to support high frequencies in the BGA test socket?

- Can the BGA socket support ultra-fine pitch?

- What kind of analysis can you provide ?

- Is there export to overseas and get local support?

- What should I do if there is a problem?

- What is the guaranteed cycle?

- What temperature can it be used in?

- I would like to consider Enplas’s test socket. What kind of information I need to provide ?

- How long does it take to deliver?