This is true for IC sockets in general: test sockets must also ensure that the device terminals and the socket probes maintain high and stable contact to consistently avoid resistance, even after repeated use.

Test socket

What is Test socket?

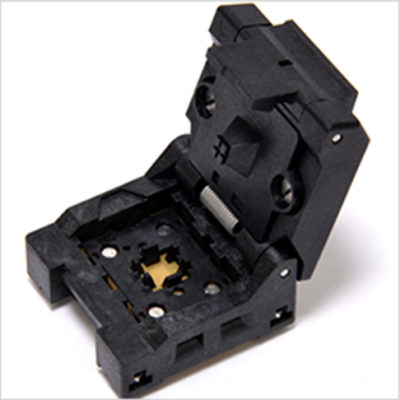

A test socket is a type of IC socket that is used to inspect the electrical characteristics of a semiconductor device to test and confirm its specifications. It can be categorized into two types: one is used for functional testing in mass production lines during the post-processing phase of semiconductor manufacturing, and the other is used for characteristic evaluation during the prototype phase of first-article products.

In contrast to the test socket, there is also the burn-in socket, which conducts accelerated testing while maintaining continuity (with power applied), whereas the test socket is used to confirm the IC function (i.e., the electrical characteristics of a semiconductor device), thereby serving a different purpose. Due to these functional differences, burn-in sockets are typically used in high-temperature environments and are often soldered to the board, making them difficult to replace. On the other hand, test sockets are utilized in the mass production process and are attached to the board via surface-mount technology (screwed in place), highlighting another difference in the mounting method.

Recent trends in electrical property testing of semiconductors

It is commonly understood that the electrical characteristics of semiconductors and devices are typically tested at room temperature using a test socket assembled in the post-process equipment of the semiconductor manufacturing process. However, recently, depending on the environment in which the semiconductors and devices are used and the required reliability, tests at both high and low temperatures have been introduced.

For instance, there has been an increase in cases where tests are conducted at temperatures ranging from -10°C to 105°C. There are also tri-temperature tests conducted at high, room, and low temperatures (150°C / room temperature / -40°C). It is crucial to ensure that operations at low temperatures for memory, as well as electrical characteristic tests, are performed at 90°C / room temperature / -40°C.

An important distinction to keep in mind here is between the electrical characteristic test and the burn-in test, which is performed in a high-temperature environment. While the burn-in test typically lasts several hours, the electrical characteristic test using a test socket (in mass production) generally lasts only a few seconds, even at high temperatures. In the case of characteristic evaluations, it sometimes takes 1 to 2 hours.

Things required for Test socket

As the demand for semiconductor electrical property tests increases, so does the role required of test sockets.

. Certainty of a function test

Longer life and durability

In particular, test sockets used for electrical characteristic test in mass production lines are required to have a longer life and durability. The main reason for this is that mass production lines have to measure a large number of semiconductors and devices, and for example, if they have a short life, they have to be replaced frequently, resulting in a decrease in productivity.

Socket spec to meet different device requirements

Compared to burn-in sockets, which prioritize continuity in high-temperature environments, test sockets have specifications designed to support waveform measurement for devices where high-frequency characteristics are crucial, as well as specifications that accommodate current and heat generation for high-current devices. It is essential for these sockets to be capable of measuring the electrical characteristics in accordance with the specific requirements of the device.

Are you encountering issues with test sockets? Are you encountering any issues?

Enplas Semiconductor Peripheral Corporation, operated by Enplas, is a leading manufacturer providing burn-in sockets as a solution for a variety of issues. Burn-in socket lineups are available for a variety of applications, devices and packages, so be sure to search according to your applicable category.

- Choose by device

- Choose by PKG

Test Socket Solutions Solutions

As devices evolve, test sockets are needed to address more and more issues everyday. Enplas Semiconductor Peripheral Corporation, operated by Enplas, offers the below solutions to address the latest issues through test sockets.

-

High-voltage (10,000V) insulation test socket.

The high-voltage test socket supports up to 10,000V and features developed large-stroke press and probe pins. We also offer a variety of contacts for different currents and can provide custom solutions.

-

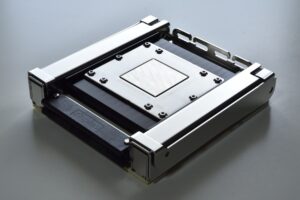

IGBT Test Socket

Stable contact performance (1000A) with high current terminals for AC/DC testing. Reduced contact marks and high durability with press contacts for insulation testing.

-

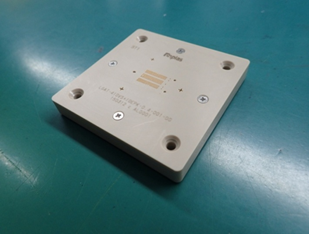

High-Frequency Socket for System-Level Testing

Enhanced Grounding and Excellent High-Frequency Characteristics Achieved by Plating the Housing

Supports PAM4 Serdes 112Gbps Operation -

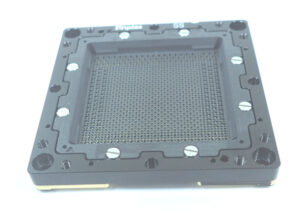

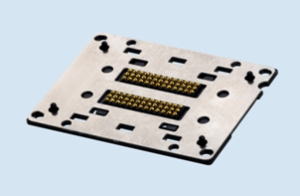

High Pin Count Solutions

Achieves stable contact performance and long life.

High current capacity is possible with integrated springs. -

Spring Kelvin Contact

Achieves stable contact performance and long life.

High current capacity is possible with integrated springs. -

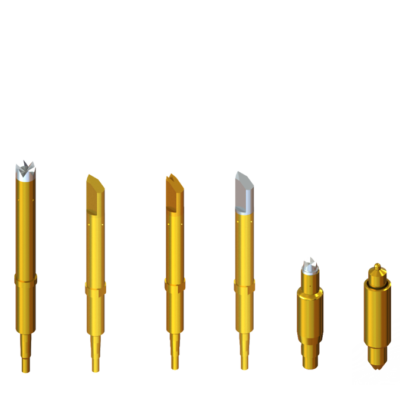

Spring Probe Pin

Enplas's own design will provide internal short circuit of probe pin with low resistance value (Ave 50m ohm or under)

Enplas provides suitable socket design proposal to meet required specification -

Chip Contactor

Huge cost reduction of chip contactor which supports high current with tooled contact pin and contact module

Moduled contact pin related component makes it easier to exchange the parts on site. -

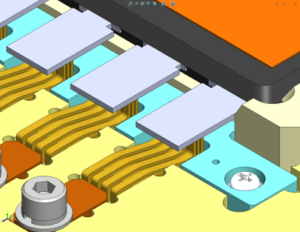

Test socket with heat pipe

The high heat dissipation capacity enabled by the heat pipe's thermal circulation structure allows for the measurement of devices with high-heat-emitting packages.

-

Conductivity Carbon Coating

Achieved a significant longer life of contacts by preventing solder migration

Achieved high durability with high slidablity and hardness -

Capsule contact

The short-length probe pin structure (total length 1.5 mm) realizes good high-frequency characteristics.

Ideal for high-speed transmission and low-voltage products -

Coaxial Contact Pin

Coaxial structure is the most suitable solution for high frequency characteristics requirement.

Minimizes crosstalk performance with shielded metal housing. -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc.

Please feel free to contact us with

your questions regarding test sockets.

Contact Us

Please contact us if you have any questions relating to test sockets. We have also compiled previous questions about IC socket solutions below, so please take a look.

- Is it possible to manufacture a socket with more than 10,000 pins?

- Can you confirm if the test socket will actually fit with my package?

- The outer dimensions (length) of the lead do not fit the standard IC sockets. Can you provide custom solutions?

- Do you have any solutions for heat dissipation?

- Can you support burn-in at temperatures above 150℃?