Solutions

Examples of Contact stability Solutions

-

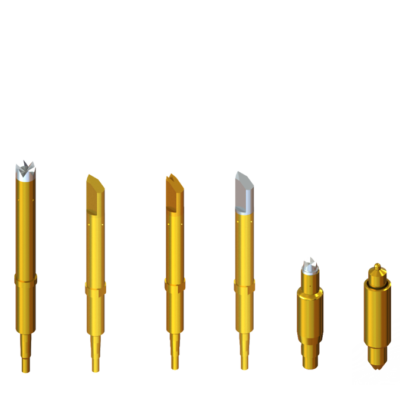

Spring Probe Pin

Enplas's own design will provide internal short circuit of probe pin with low resistance value (Ave 50m ohm or under)

Enplas provides suitable socket design proposal to meet required specification -

Curling Contact Series

Cost saving solution with the same performance as probe pin

Long stroke pin which works for device warpage in accordance with recent large size device -

Low Contact Force Pin

High pin count socket can be used for existing equipment

Yield improvement in test of sensor device -

Chip Contactor

Huge cost reduction of chip contactor which supports high current with tooled contact pin and contact module

Moduled contact pin related component makes it easier to exchange the parts on site. -

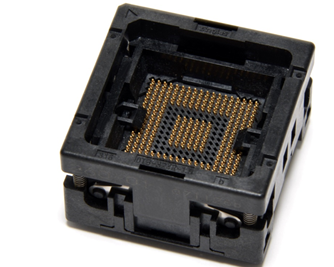

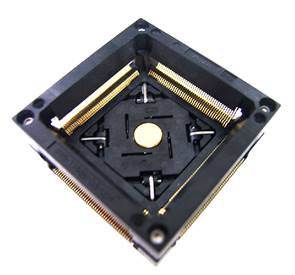

Open top BGA two contact socket

Stable contact performance due to (two-point contact) structure

Double door structure makes it easy to insert PKG -

Open Top QFP/SOP pinch type socket

Pinch type contact (2-point contact) makes stable contact

Contact pin surface cleaning function prevents from accumulating debris due to the step between the bottom pin and the molded body surface. -

Conductivity Carbon Coating

Achieved a significant longer life of contacts by preventing solder migration

Achieved high durability with high slidablity and hardness -

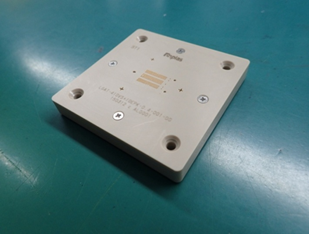

High pin count BGA socket (VC contact)

Stamped contact pin and molded frame realize significant cost reduction for large PKG

Replacible on site by surface mounting method -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc. -

AM contact series

Low price and quick delivery for various devices by using machined Contact unit

Replacible on site by surface mounting method