Solutions

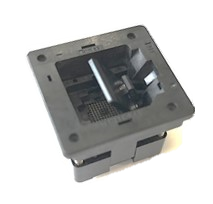

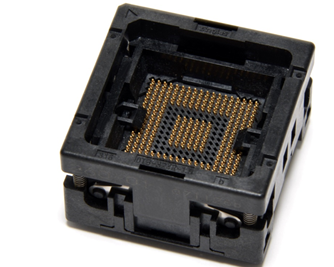

Open Top Socket with Cover

- Open top socket integrated with a mechanism that protects the entire top surface of the PKG.

- Socket with cover to prevent dust in the air from coming into the socket.

- Ideal solution for protecting image sensors.

This socket is a product called open top socket with cover for preventing foreign material contamination.

As the name suggests, the socket has a cover already assembled, and after inserting the image sensor into the socket, the cover can physically shut out the fine dust and dirt in the air, which can avoid damading the glass surface of the image sensor.

This socket also has the hardstop feature, and the cover will not touch the glass surface of the image sensor.

The integrated cover structure is designed inside the socket, which achieved to keep the compact socket size.In summary, this socket is recommended for those who want to prevent foreign material contamination and also for those who want to avoid the damage to the glass surface of the image sensor.

Examples of IC Socket Solutions Solution Examples

- All Solutions

- Choose by application

- Choose by device

- Choose by PKG

- Choose by issue

Examples of Image sensor Solutions

-

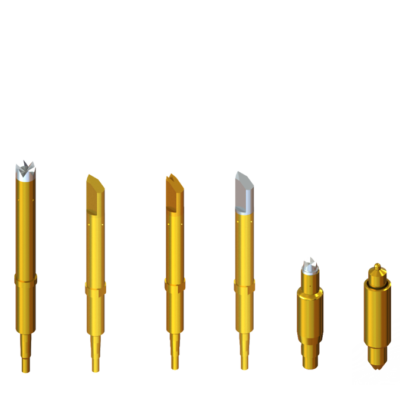

Spring Probe Pin

Enplas's own design will provide internal short circuit of probe pin with low resistance value (Ave 50m ohm or under)

Enplas provides suitable socket design proposal to meet required specification -

Curling Contact Series

Cost saving solution with the same performance as probe pin

Long stroke pin which works for device warpage in accordance with recent large size device -

Low Contact Force Pin

High pin count socket can be used for existing equipment

Yield improvement in test of sensor device -

Non-magnetic Socket

Non-magnetic socket will be required for sensor application

Corrosion resistance with non-magnetic performance -

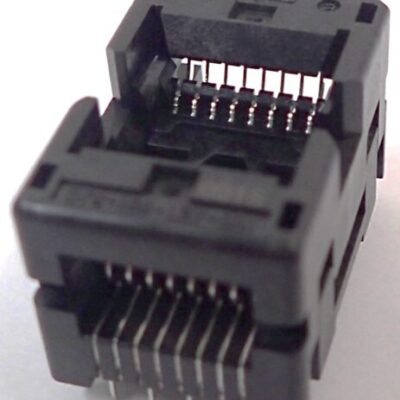

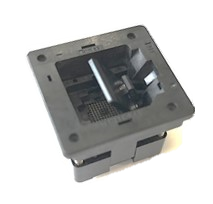

Open top BGA two contact socket

Stable contact performance due to (two-point contact) structure

Double door structure makes it easy to insert PKG -

LCF series (general-purpose molded frame)

Low price and quick delivery for various devices up to 100mmx100mm

Replacible on site by surface mounting method -

Open Top Socket with Cover

Open top socket integrated with a mechanism that protects the entire top surface of the PKG.

Socket with cover to prevent dust in the air from coming into the socket. -

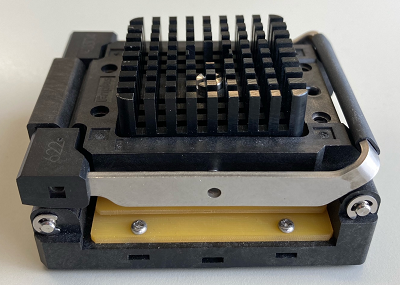

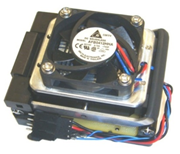

Socket with heat sink

Heat Sink will reduce the increase of device temperature by contacting device surface with this parts and radiating the device heat into the air.

-

Individual Temparature Control System

Heater and temperature sensors can be attached to control the temperature of the device for each socket.

Achieves more accurate temperature control in comparison with general burn-in equipment (temperature setting ± 3 ° C) -

Conductivity Carbon Coating

Achieved a significant longer life of contacts by preventing solder migration

Achieved high durability with high slidablity and hardness -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc. -

AM contact series

Low price and quick delivery for various devices by using machined Contact unit

Replacible on site by surface mounting method