Solutions

Examples of QFP Solutions

-

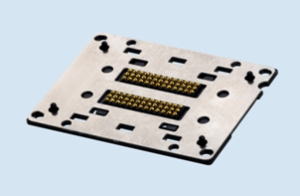

High-Frequency Socket for System-Level Testing

Enhanced Grounding and Excellent High-Frequency Characteristics Achieved by Plating the Housing

Supports PAM4 Serdes 112Gbps Operation -

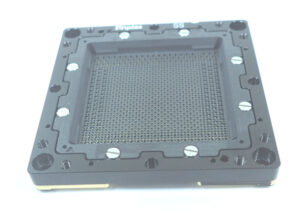

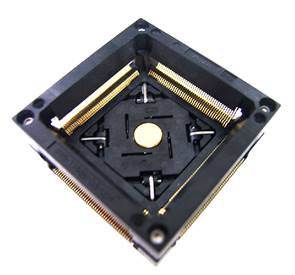

High Pin Count Solutions

Achieves stable contact performance and long life.

High current capacity is possible with integrated springs. -

Spring Kelvin Contact

Achieves stable contact performance and long life.

High current capacity is possible with integrated springs. -

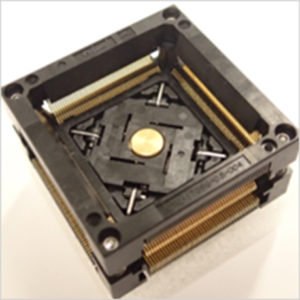

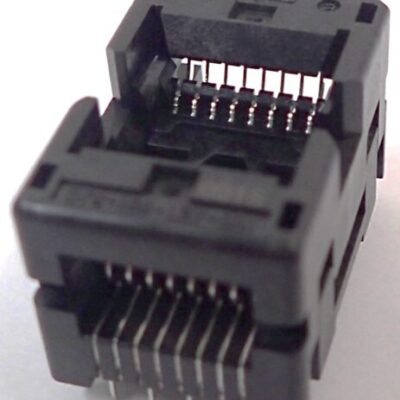

QFP/SOP Open Top Socket with Ground Pins

Stable Contact Performance with Cantilever Structure (2-Point Contact)

Ground Pins for Continuity Testing and Heat Dissipation Pins for High-Heat Packages -

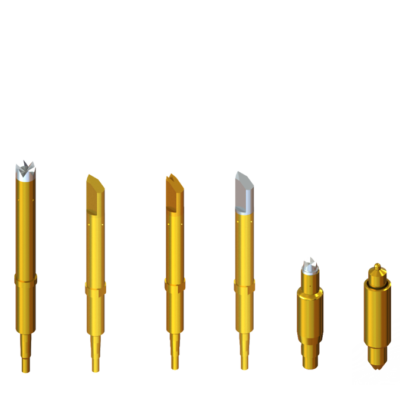

Spring Probe Pin

Enplas's own design will provide internal short circuit of probe pin with low resistance value (Ave 50m ohm or under)

Enplas provides suitable socket design proposal to meet required specification -

Non-magnetic Socket

Non-magnetic socket will be required for sensor application

Corrosion resistance with non-magnetic performance -

Open Top QFP/SOP pinch type socket

Pinch type contact (2-point contact) makes stable contact

Contact pin surface cleaning function prevents from accumulating debris due to the step between the bottom pin and the molded body surface. -

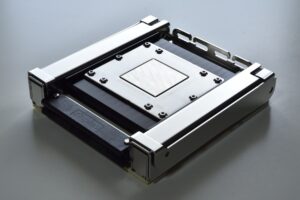

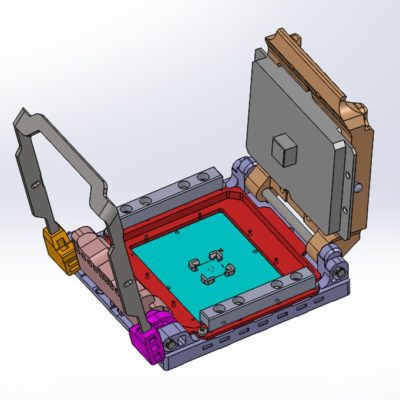

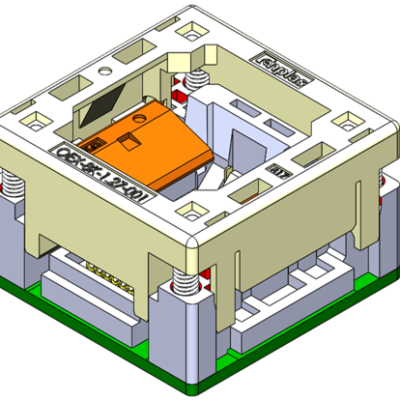

Custom socket for high power liquid cooling system

Not only BGA, and LGA, but also various type of package including QFN can be designed by using a socket that is suitable for the thermal head size

-

LCF series (general-purpose molded frame)

Low price and quick delivery for various devices up to 100mmx100mm

Replacible on site by surface mounting method -

Sockets for power devices

Compatible with various power devices that are not handled by other companies

It is also possible to consider the optimum pin arrangement and support large currents of power devices. -

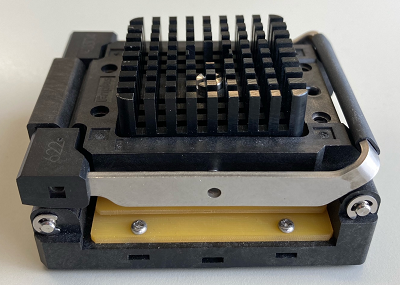

Socket with heat sink

Heat Sink will reduce the increase of device temperature by contacting device surface with this parts and radiating the device heat into the air.

-

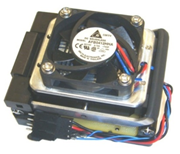

Individual Temparature Control System

Heater and temperature sensors can be attached to control the temperature of the device for each socket.

Achieves more accurate temperature control in comparison with general burn-in equipment (temperature setting ± 3 ° C) -

Conductivity Carbon Coating

Achieved a significant longer life of contacts by preventing solder migration

Achieved high durability with high slidablity and hardness -

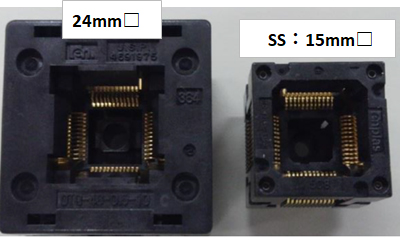

Super Shrink Socket

Increase of BIB density (1.8 times better density rate per 1 BIB)

In the condition of same socket qty, the reduction of BIB qty (45% reduction) -

Capsule contact

The short-length probe pin structure (total length 1.5 mm) realizes good high-frequency characteristics.

Ideal for high-speed transmission and low-voltage products -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc. -

AM contact series

Low price and quick delivery for various devices by using machined Contact unit

Replacible on site by surface mounting method