Solutions

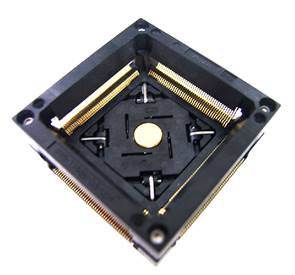

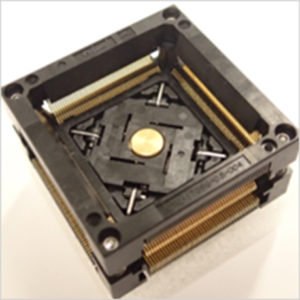

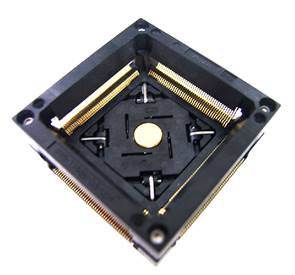

Open Top QFP/SOP pinch type socket

- Pinch type contact (2-point contact) makes stable contact

- Contact pin surface cleaning function prevents from accumulating debris due to the step between the bottom pin and the molded body surface.

This socket is open top type used for QFP / SOP packages.

As a feature, stable contact performance with the sandwiching structure of two-point contact and a unique cleaning function for the pin contact surface.

Normally, when a two-point contact sandwiching structure is used, debris will accumulate due to the step between the bottom pin and the molded body surface, but our unique cleaning function prevents the debris from accumulating, which can lead to easy meintenance (cleaning) during use by the customer and makes it possible to reduce running costs.

Examples of IC Socket Solutions Solution Examples

- All Solutions

- Choose by application

- Choose by device

- Choose by PKG

- Choose by issue

Examples of Analog Solutions

-

QFP/SOP Open Top Socket with Ground Pins

Stable Contact Performance with Cantilever Structure (2-Point Contact)

Ground Pins for Continuity Testing and Heat Dissipation Pins for High-Heat Packages -

Non-magnetic Socket

Non-magnetic socket will be required for sensor application

Corrosion resistance with non-magnetic performance -

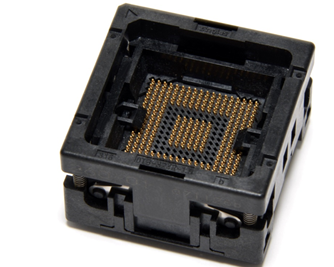

Open top BGA two contact socket

Stable contact performance due to (two-point contact) structure

Double door structure makes it easy to insert PKG -

Open Top QFP/SOP pinch type socket

Pinch type contact (2-point contact) makes stable contact

Contact pin surface cleaning function prevents from accumulating debris due to the step between the bottom pin and the molded body surface. -

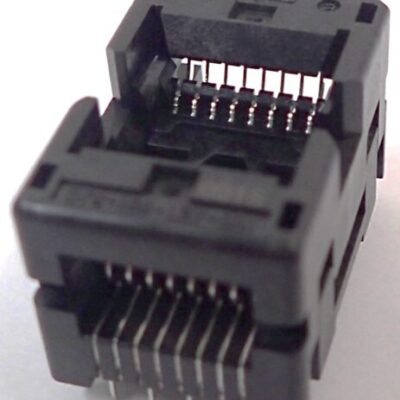

LCF series (general-purpose molded frame)

Low price and quick delivery for various devices up to 100mmx100mm

Replacible on site by surface mounting method -

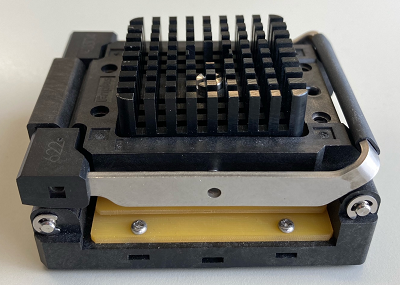

Socket with heat sink

Heat Sink will reduce the increase of device temperature by contacting device surface with this parts and radiating the device heat into the air.

-

Conductivity Carbon Coating

Achieved a significant longer life of contacts by preventing solder migration

Achieved high durability with high slidablity and hardness -

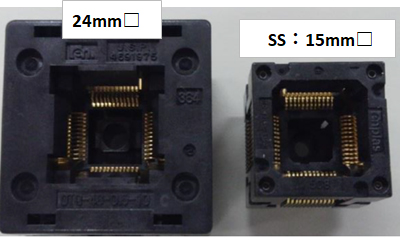

Super Shrink Socket

Increase of BIB density (1.8 times better density rate per 1 BIB)

In the condition of same socket qty, the reduction of BIB qty (45% reduction) -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc. -

AM contact series

Low price and quick delivery for various devices by using machined Contact unit

Replacible on site by surface mounting method