Solutions

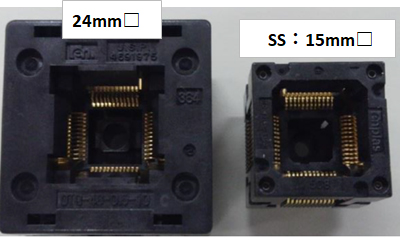

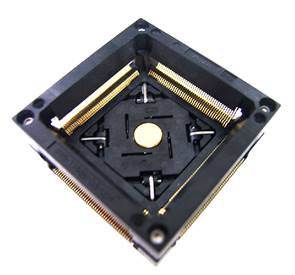

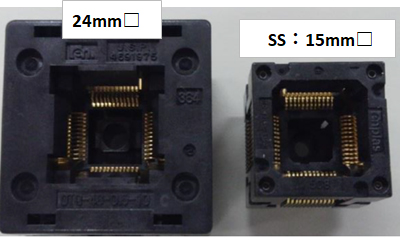

Super Shrink Socket

- Increase of BIB density (1.8 times better density rate per 1 BIB)

- In the condition of same socket qty, the reduction of BIB qty (45% reduction)

Super Shrink Socket has the features below:

-40% and more small size of socket surface area sompared to our previous socket

-Density increase of BIB brings throuth-put of burn in process (“through-put” means the number of processed device per unit time).

– BIB produciton cost reduction because of smaller BIB qty

– Parts count reduction (11 -> 5 in QFN open top socket)

This socket will be good fit for BIB density increase or reduction of BIB qty with same socket qty.

Examples of IC Socket Solutions Solution Examples

- All Solutions

- Choose by application

- Choose by device

- Choose by PKG

- Choose by issue

Examples of Analog Solutions

-

QFP/SOP Open Top Socket with Ground Pins

Stable Contact Performance with Cantilever Structure (2-Point Contact)

Ground Pins for Continuity Testing and Heat Dissipation Pins for High-Heat Packages -

Non-magnetic Socket

Non-magnetic socket will be required for sensor application

Corrosion resistance with non-magnetic performance -

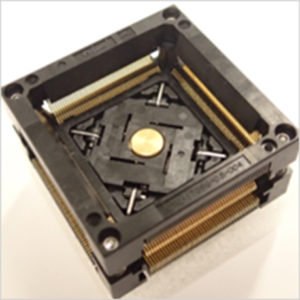

Open top BGA two contact socket

Stable contact performance due to (two-point contact) structure

Double door structure makes it easy to insert PKG -

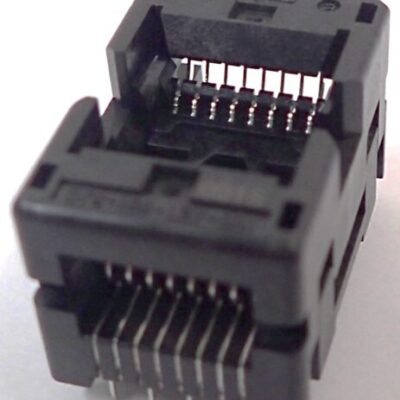

Open Top QFP/SOP pinch type socket

Pinch type contact (2-point contact) makes stable contact

Contact pin surface cleaning function prevents from accumulating debris due to the step between the bottom pin and the molded body surface. -

LCF series (general-purpose molded frame)

Low price and quick delivery for various devices up to 100mmx100mm

Replacible on site by surface mounting method -

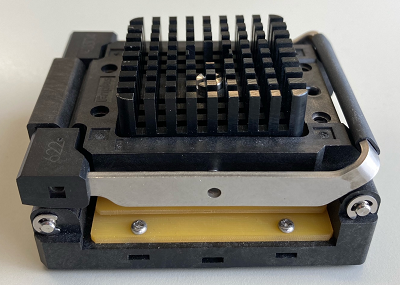

Socket with heat sink

Heat Sink will reduce the increase of device temperature by contacting device surface with this parts and radiating the device heat into the air.

-

Conductivity Carbon Coating

Achieved a significant longer life of contacts by preventing solder migration

Achieved high durability with high slidablity and hardness -

Super Shrink Socket

Increase of BIB density (1.8 times better density rate per 1 BIB)

In the condition of same socket qty, the reduction of BIB qty (45% reduction) -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc. -

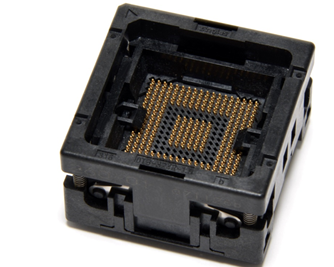

AM contact series

Low price and quick delivery for various devices by using machined Contact unit

Replacible on site by surface mounting method