IC Socket Technical Information

The surface mounting method of IC sockets Explanation of terminal shape, PKG type and type

2024.09.27

IC sockets are tools for electrically connecting ICs to printed circuit boards for the purpose of checking the electrical characteristics of ICs and evaluating their reliability. They are designed to be removable and insertable so that the characteristics of a large number of ICs can be repeatedly evaluated.

IC socket mounting methods are divided into two types: surface mounting and insertion mounting.

Introduction to PKG types for each IC socket terminal shape

Surface mounting of IC sockets is a method of attaching electronic components directly to the surface of a substrate and serves as an interface to connect IC chips to the substrate without soldering. The surface mounting method has the advantage that IC sockets can be easily replaced, improving the efficiency of measures, repairs, and maintenance. This mounting method enables high-density mounting and is widely used in today’s miniaturized and high-performance electronic components.

And the terminal shapes of surface-mount IC sockets are classified into 2-sided, 4-sided, and lattice shapes.

The following is an introduction to each terminal shape and the corresponding PKG type and classified type.

2-sided terminals

The 2-sided terminal is a terminal shape in which the terminals (leads) protrude from two sides of the package.

The following is an introduction to the applicable PKG types.

PKG type with 2-sided terminals: SOP (Small Outline Package)

SOP, one of the 2-sided terminal packages, is a small and lightweight package with a gull wing lead shape.

The advantages of SOP are not only its low cost due to mass production, but also its relatively sturdy structure and resistance to vibration and shock since the lead portion is elastically deformed.

4-Side Terminals

4-sided terminals are a terminal shape in which the terminals (leads) protrude from four sides of the package.

The following is a list of applicable PKG types.

PKG type with 4-sided terminals: QFP (Quad Flat Package)

QFP is a flat, thin, planar package with gull wing type leads. The leads are evenly distributed on each side, resulting in low inductance and improved heat dissipation performance. This makes QFPs suitable for automotive and communication equipment. Furthermore, QFPs have the advantage of high reliability because visual inspection of soldering is possible and inspection is easy.

PKG type with 4-sided terminals: QFN (Quad Flat Non-leaded package)

QFN is small because the terminals (leads) do not protrude from the sides of the package and are short, and the electrode pads are connected to the substrate as terminals. A large pad exposed in the center for heat dissipation helps dissipate heat. The very small size and light weight of the package make it suitable for portable equipment and portable devices.

Grid Terminals

Lattice terminals are a form of package in which the terminals are arranged in a grid pattern on the bottom of the package. This format increases the overall contact points of the package, improving electrical connection and mechanical strength.

PKG Type with Grid Terminals: Land Grid Array (LGA)

LGA consists of a grid of flat land pads on the bottom of the package. These pads are connected to corresponding contact points on the socket or board to enable high-density mounting. The large contact area between the pads and the socket makes the PKG highly reliable as it is less prone to contact failures.

PKG type with grid terminals: Ball Grid Array (BGA)

BGA is a thin and compact package with ball-shaped solder balls arranged in a grid pattern on the bottom of the package. This enables high-speed signal transmission and stable mechanical strength.

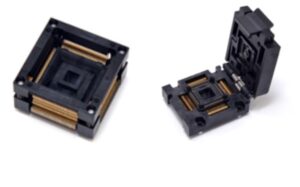

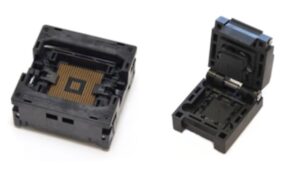

Open-top type Clamshell type

Introduction to the two socket types

Sockets for the PKGs described above can be further classified into two types: open-top and clamshell.

The open-top type sockets have an open top that allows easy insertion and removal of ICs from the top, and are highly accurate in operation because the IC insertion status can be visually confirmed.

Clamshell sockets are designed to open and lock at the top and bottom, much like a bivalve shell, and provide high signal quality and a stable connection against vibration and shock by firmly securing the IC. Because of these advantages, clamshell sockets are used to identify problems with the operation and connection of specific ICs.

Our Solutions Include

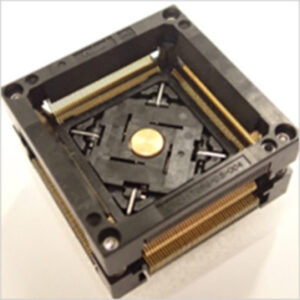

Open-top sockets with QFP/SOP ground pins

These sockets are open-top sockets with QFP/SOP ground pins,

It features a ground pin attached to a 2-point open-top socket with a pincer structure for stable contact performance. The ground pin is available with a horseshoe pin for continuity testing and with a heat-dissipating pin to prevent heat generation in PKGs.

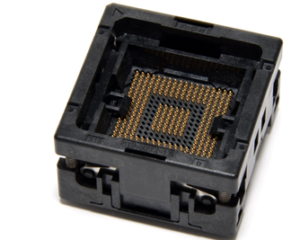

Open-top BGA Pinching Sockets

This socket is a pinched open-top BGA socket.

The pincer structure ensures stable contact.

The advantage of the sandwich structure is that the damage to the solder balls is small, thus reducing the impact on the mounting process.

>>Click here for more details.

Conclusion

How was it? In this article, we introduced IC socket mounting methods, shapes, and PKG types.

Enplas Semiconductor Equipment Corporation, which operates IC-Socket-Solution.com, is a leading manufacturer of burn-in sockets and test sockets!

Technical Information on Sockets in Same Category

-

2024.10.10

Explanation of Temperature Cycling Test (TCT)

-

2024.09.27

The surface mounting method of IC sockets Explanation of terminal shape, PKG type and type

-

2024.07.1

Explanation of the Features and Mechanism of the Temperature Humidity Bias (THB) Test

-

2024.07.1

Explanation of the Features and Mechanism of the High Accelerated Stress Test (HAST)

-

2021.05.18

What is IC socket?