Solutions

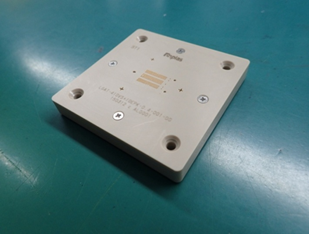

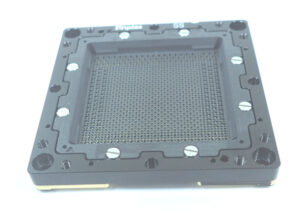

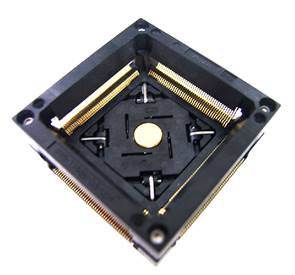

Chip Contactor

- Huge cost reduction of chip contactor which supports high current with tooled contact pin and contact module

- Moduled contact pin related component makes it easier to exchange the parts on site.

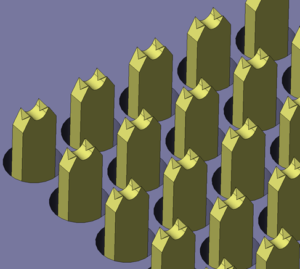

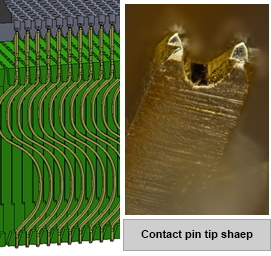

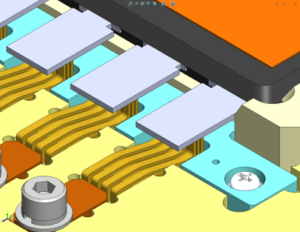

Chip contactor has stable contact performance with 4 point pin tip. You can select 0.4mm or 0.35mm pitch in accordance with package pad location or required current specification.Moduled contact pin related component makes it easier to exchange the parts on site.

You can choose different kind of contact pin within same module (for signal, we use probe pin, for high current pad, we can choose high current compatible pin).

This contactor will be used for surface mount LGA type power device.

We can use this socket for next generation IGBT 1200A with stable contact on high current electrical pad.

High allowable current pin Probe pin for signal

Examples of IC Socket Solutions Solution Examples

- All Solutions

- Choose by application

- Choose by device

- Choose by PKG

- Choose by issue

Examples of Power Solutions

-

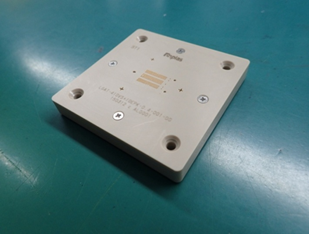

High-voltage (10,000V) insulation test socket.

The high-voltage test socket supports up to 10,000V and features developed large-stroke press and probe pins. We also offer a variety of contacts for different currents and can provide custom solutions.

-

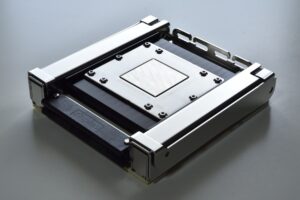

IGBT Test Socket

Stable contact performance (1000A) with high current terminals for AC/DC testing. Reduced contact marks and high durability with press contacts for insulation testing.

-

High-Frequency Socket for System-Level Testing

Enhanced Grounding and Excellent High-Frequency Characteristics Achieved by Plating the Housing

Supports PAM4 Serdes 112Gbps Operation -

High Pin Count Solutions

Achieves stable contact performance and long life.

High current capacity is possible with integrated springs. -

Spring Kelvin Contact

Achieves stable contact performance and long life.

High current capacity is possible with integrated springs. -

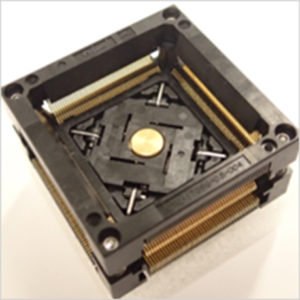

QFP/SOP Open Top Socket with Ground Pins

Stable Contact Performance with Cantilever Structure (2-Point Contact)

Ground Pins for Continuity Testing and Heat Dissipation Pins for High-Heat Packages -

Chip Contactor

Huge cost reduction of chip contactor which supports high current with tooled contact pin and contact module

Moduled contact pin related component makes it easier to exchange the parts on site. -

Open Top QFP/SOP pinch type socket

Pinch type contact (2-point contact) makes stable contact

Contact pin surface cleaning function prevents from accumulating debris due to the step between the bottom pin and the molded body surface. -

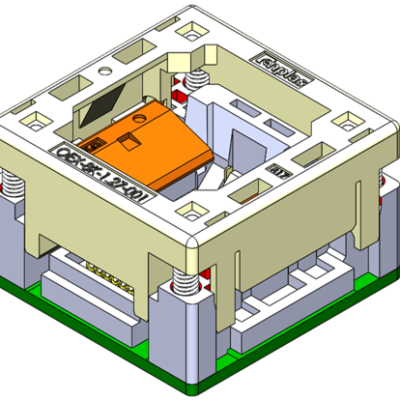

Sockets for power devices

Compatible with various power devices that are not handled by other companies

It is also possible to consider the optimum pin arrangement and support large currents of power devices. -

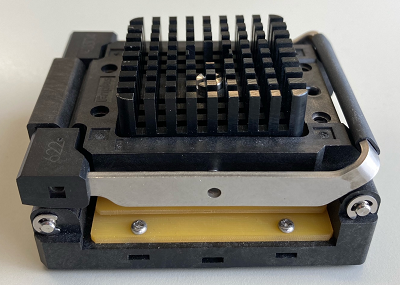

Socket with heat sink

Heat Sink will reduce the increase of device temperature by contacting device surface with this parts and radiating the device heat into the air.

-

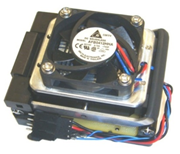

Individual Temparature Control System

Heater and temperature sensors can be attached to control the temperature of the device for each socket.

Achieves more accurate temperature control in comparison with general burn-in equipment (temperature setting ± 3 ° C) -

Conductivity Carbon Coating

Achieved a significant longer life of contacts by preventing solder migration

Achieved high durability with high slidablity and hardness -

ES Plating

By developing special plating (ES plating), the life of burn-in socket contacts has been extended in high temperature environments.

Maintenance costs have also been significantly reduced by reducing re-gold plating costs, etc. -

AM contact series

Low price and quick delivery for various devices by using machined Contact unit

Replacible on site by surface mounting method