We solve all problems in IC sockets by providing and developing cutting-edge solutions.

Why IC Socket Solutions.com is your choice

Reason #1

We provide cutting-edge solutions aligned with the trends of the world's leading semiconductor manufacturers.

In recent years, there have been increasing challenges with devices that require smaller form factors and higher currents. Enplas, which operates ICSocketSolutions.com, develops new technologies and leading solutions by keeping up with global semiconductor trends.

To develop new solutions and accelerate development speed, we have development and design centers worldwide, enabling us to provide dedicated and timely support to our customers.

Reason #2

We provide IC socket that solve customer problem with our advanced solutions.

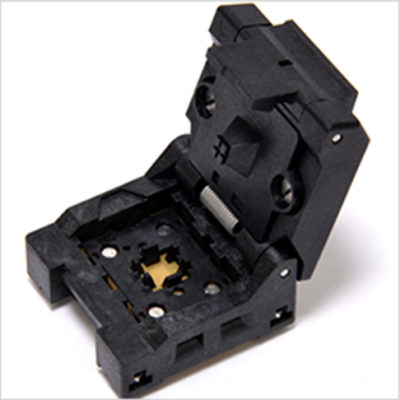

Enplas is a leading manufacturer of burn-in and test sockets. We have developed advanced coating solutions for contact pins and high-frequency solutions that withstand high-temperature environments, extending their durability. For more information about our products and solutions, please visit the link below.

Not only custom solutions, we also have a great or selections for standard socket .

We manufacture custom products tailored to meet customer needs. Additionally, we offer a wide selection of standard sockets that cater to various package and device requirements. For more information, please check the supported packages using the link below.

Choose by PKG

Reason #3

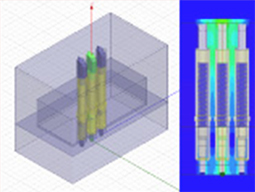

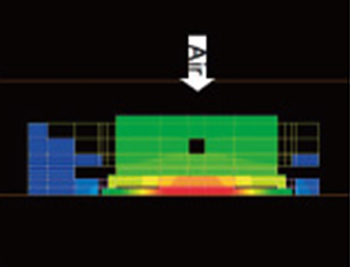

Provide the reliable and fast product development with advanced simulation technology

For burn-in and test sockets, which often require custom solutions, it is important to perform simulations for each individual device in a timely manner in order to shorten the development and manufacturing lead times. IC socket solutions provide a platform that can perform electrical, thermal, mechanical, and 3D analyses. Additionally, the total development lead time can be shortened by performing strength and flow analyses, and by selecting the most suitable socket type and options.

Recently, burn-in sockets and test sockets have required a low-volume, high-mix development approach. Our strength lies in our ability to quickly develop products using these simulation technologies and a broad range of product lineups.

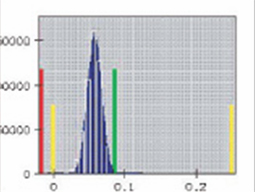

Main Simulation Technologies Offered

by Enplas Semiconductor Peripheral Corporation

3D electromagnetic field SImulation

Thrmal Simulation

Strength Simulation

3D Operation Check

Flow Analysis